Product Details

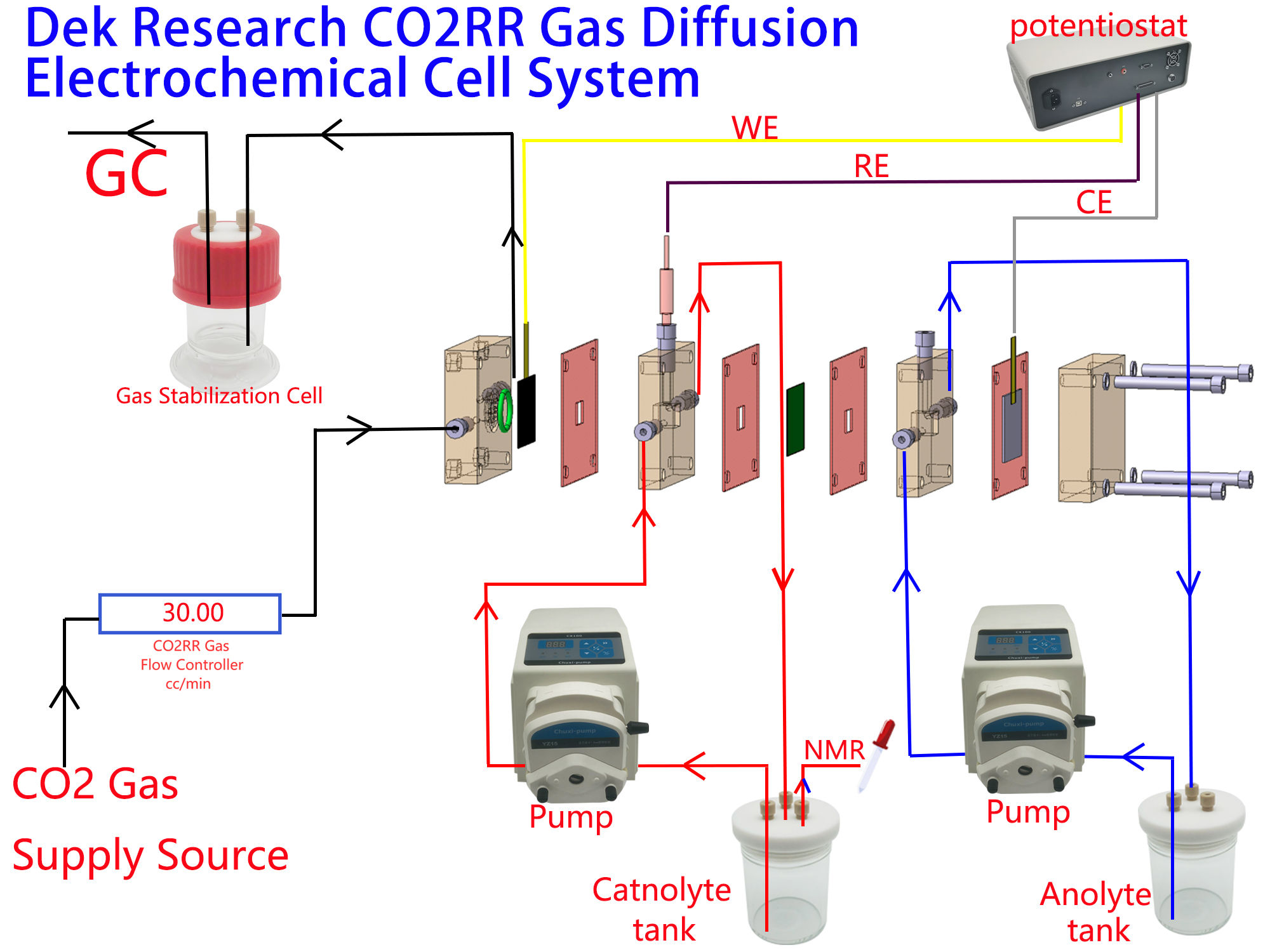

In the ongoing development of electrocatalytic carbon dioxide reduction (CO2RR) technology, researchers have discovered that by using a gas diffusion electrode (GDE) with a flowing catholyte, it is possible to evaluate the electrocatalytic performance of these catalysts regardless of mass transfer limitations and local pH effects. That is, a so-called flow electrolytic cell is constructed to replace the static H-type electrolytic cell in the traditional sense.

In the flow electrolysis cell, CO2 enters the cathode of the electrolysis cell from the back of the gas diffusion layer, and reacts with H+ from the electrolyte in the cathode catalytic layer to be reduced, and the reduction product is discharged from the electrolysis cell through the gas diffusion layer.

The flow electrolysis cell can not only alleviate the mass transfer polarization caused by the low solubility of CO2 in water, but also suppress the hydrogen evolution side reaction due to the use of a flowing electrolyte, and reduce the CO2 activation energy barrier and enhance the CC coupling between *CO, thereby increasing the selectivity of the C2 product.Continuous reaction can bring the advantage of no backflow of materials, so that the product can not be over oxidated and reduced, and the product yield can be improved.

Characteristic:

1. Compared with the usual H-type electrolytic cell, the liquid flow electrolytic cell has more advantages in liquid phase mass transfer kinetics.

2. Directly supply CO2 gas to the cathode, which overcomes the disadvantages of low solubility and slow diffusion of CO2 gas in aqueous solution.

3.The thickness of the electrode plate can be customized according to the needs, which can effectively shorten the distance between the anode and the anode, reduce the resistance, and improve the test efficiency.

Parameter:

1.The main body of the flow cell is made of PEEK and PMMA material, which is made by meticulous crafting.

2.The designed working area of the flow cell is 4cm2, which is square 20*20mm. Other areas can also be customized according to user requirements.

3.Chamber A is used for CO2 gas inlet and outlet, and its outer size is 60*60*20mm. The flow channel adopts the S-shaped flow channel, which can make the CO2 flow in along the S-shaped direction next to the GDE, and then output from the end of the flow channel to the online chromatographic detection and analysis. We use a unique design. Choose a gasket whose thickness is less than the thickness of GDE, and place it on the outside of GDE, so that the GDE should be centered as much as possible during installation. When the entire device is assembled, tighten the four fixing rods to achieve the GDE and S-shaped runners close to each other and achieve a sealing effect.The chamber A is made of PMMA organic glass. After polishing, the gas flow channel can be directly observed, which is helpful to observe whether the catholyte enters the flow channel through the GDE.

4.Chamber B is used as a catholyte cell, and its outer size is 60*60*15mm. The catholyte is circulated through a peristaltic pump. A φ6mm reference electrode is placed on the top of the chamber.

5.Chamber C is used as an anolyte cell, and its outer size is 60*60*15mm. Considering that the anode material produces more oxygen, when the anolyte is also circulated through the peristaltic pump, the holes 5 and 6 are used as the anolyte inlet and outlet. At this time, use a solid sealing screw to block the hole 7. Alternatively, the hole 7 can be used as a circulation outlet hole, and the hole 6 can be blocked with a sealing screw. When the anolyte is not circulating, use solid sealing screws to block both holes 5 and 6, and open hole 7 for exhaust.

6.Chamber D is used as a fixed plate, and the outer size is 60*60*20mm.

7.When the anode uses foamed nickel material or mesh material, the anode can be clamped between the chambers C and D. It can also be clamped between the ion membrane and the chamber C, which can further shorten the distance between the cathode and the anode and reduce the internal resistance.But a very important reminder is that the user must inform us of the thickness of the anode material used, so that we can match it with a corresponding gasket to avoid the leakage of the anode liquid from the thickness of the nickel foam or the mesh material.

8.The conductive current collector equipped with this device is a copper foil with adhesive backing. Its thickness is 65um, which not only has good conductivity, but the thickness does not affect the sealing of the entire device. Users can also replace the appropriate conductive current collector according to their needs.

9.The flow cell can be quickly assembled and disassembled, and it is easy to clean.

Product Includes: 1 * Flow cell 2 * Ag/AgCl reference electrode Φ6*70mm glass rod 1 * Conductive copper foil 1 * 3mm PTFE tube 1 * Cutting knife 6 * PUφ3mm quick connect 4 * Positioning rod 2 * Allen key 8 * 304 stainless steel fixing rod 3 * Electrode hole sealing screw 3 * Liquid hole solid sealing screw 12 * Gas/liquid hole sealing screw 12 * Fluorine rubber gasket 12 * Silicone gasket 30 * fluorine rubber O-ring

References:

NEED HELP? CONTACT US

Call Toll-Free +1 (800) 972-7086

Email Us:

- Shipping

- Standard Shipping: 5-7 Business days

- DHL/Fedex Express Shipping: 2-5 Business days

PAYMENT

United States (USD)

United States (USD) Canada (CAD)

Canada (CAD) Australia (AUD)

Australia (AUD) Singapore (SGD)

Singapore (SGD) New Zealand (NZD)

New Zealand (NZD) Ireland (EUR)

Ireland (EUR) India (INR)

India (INR)